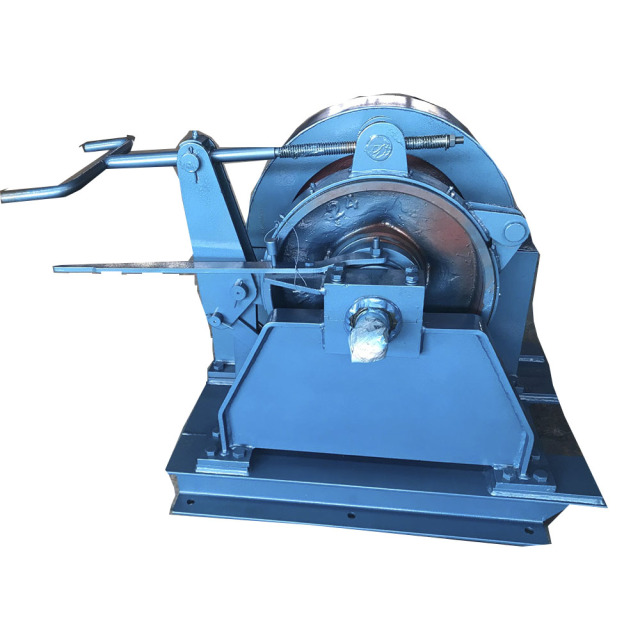

Presentation of structure.

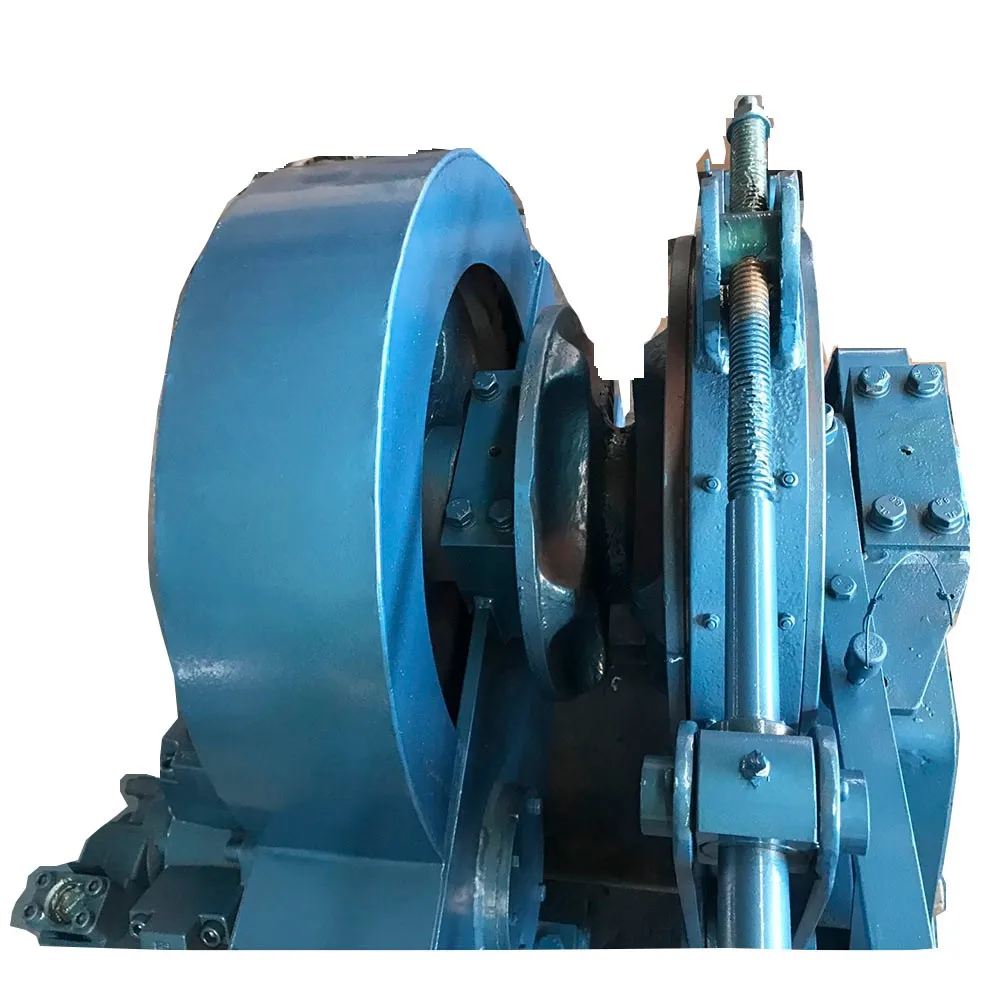

This hydraulic anchor winch consists of gear reducer, base, clutch,brakes,drum, warping head, spindle, hydraulic system, etc.

| Name | Sino-Winch-24 | |

| 1 | Anchor chain diameter | 24mm |

| 2 | Working load | 24.48 kN |

| 3 | Overload pull | 36.72 kN |

| 4 | Supporting load | 149.4kN |

| 5 | Nominal speed | ≥9m/min |

| 6 | Anchoring depth | ≤82.5m |

| 7 | Reel load | 15kN |

| 8 | Hydraulic motor | JMDG6-700B |

| 9 | Oil pump | 40SCY14-1B |

| 10 | System working pressure | 8.2MPa |

| 11 | Adjusted pressure of Safety valve | 13.5MPa |

| 12 | System flow | 60L/min |

|

|

|

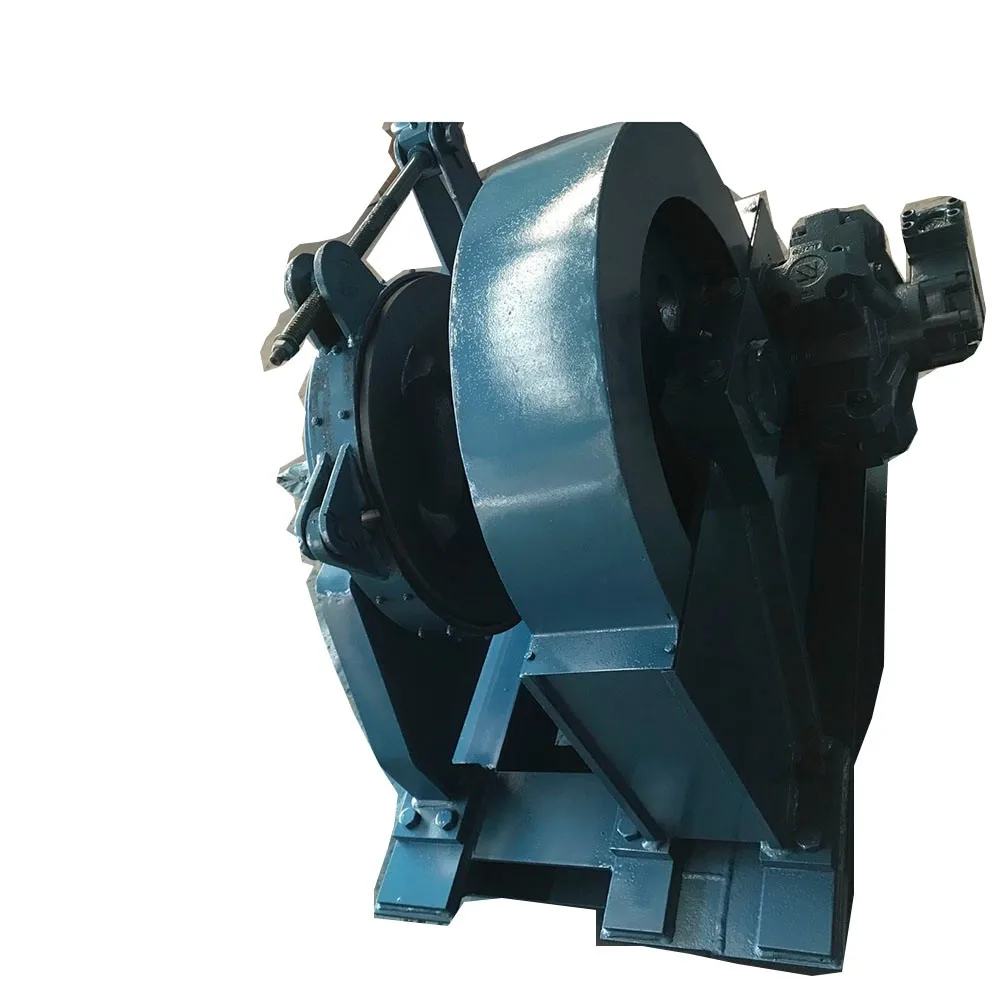

Machine PartsName: Gear reducer

The hydraulic anchor winch gear reducer adopts open gear transmission, The system has the advantages of high efficiency, large bearing load and easy lubrication, etc. Passive gear will transfer the power to the shaft of anchor wheel. |

|

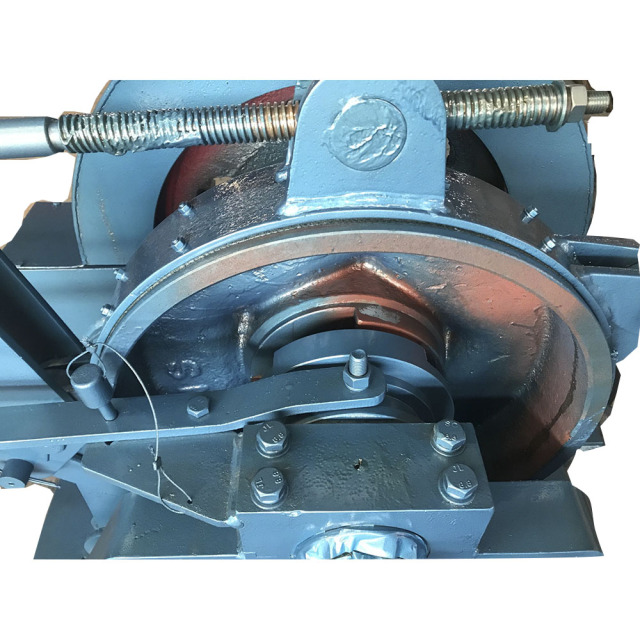

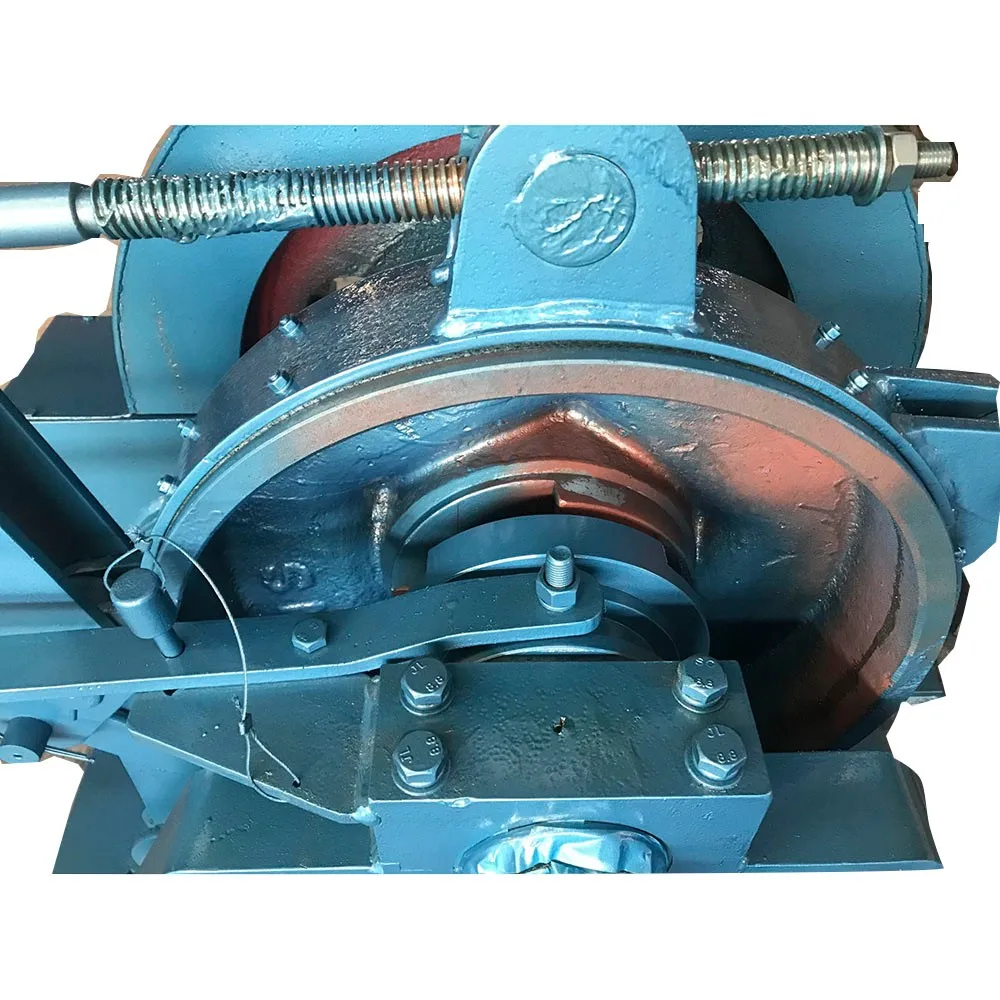

Machine PartsName: Brake |

|

|

|

| Machine Parts Name: Clutch The clutch is used to control the separation and closing of the jaw clutch. When weighing anchor ,controlthe clutch handle of anchor drumto close the clutch,disengage the clutch of mooring drum;When mooring,disengage the clutch of anchor drum ,close the clutch of mooring drum. |

|

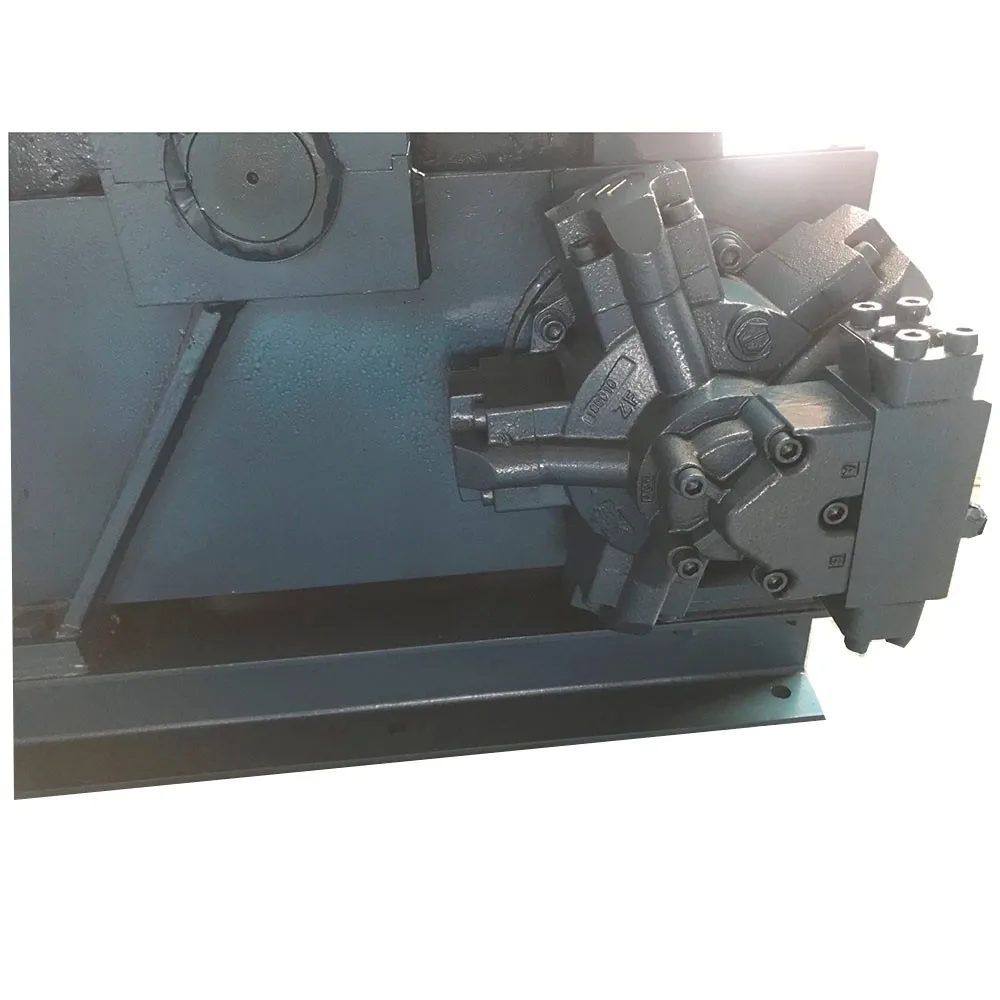

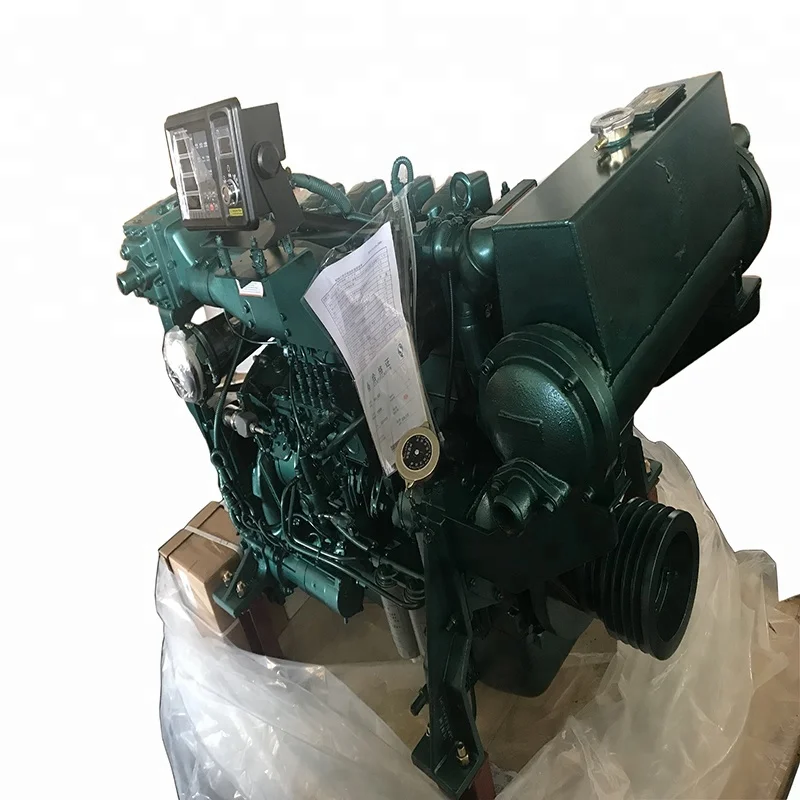

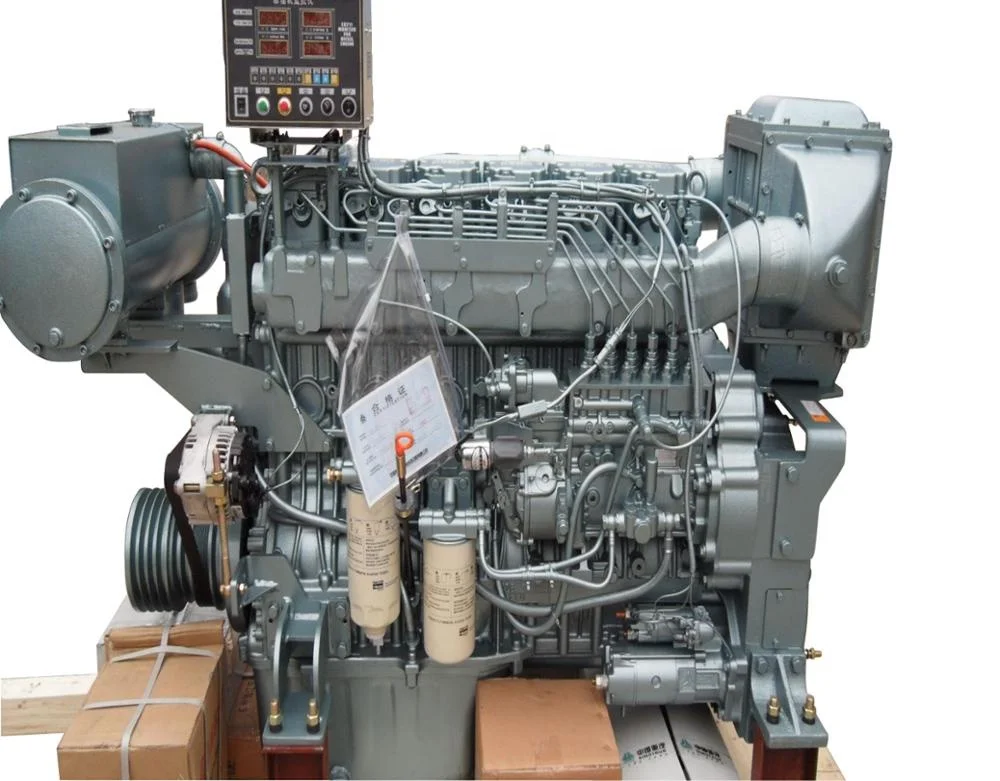

Machine PartsName: Power unit

Power unit consists of tank, motor driven hydraulic pump etc. The oil tank is welded with steel plate, the tank is provided with a partition board, and the inlet and the outlet are separated.The oil tank is provided with a hydraulic pressure indicator, and a return oil filter is arranged on the oil tank;The electric motor and the oil pump are positioned below the oil tank, connected with an elastic coupling, they provide pressure oil for the hydraulic motor of the anchor winch. |

| Tube diameter | Space of tube clamps |

| 10~25 | ≤1500 |

| >25~50 | ≤2000 |

| >50~80 | ≤3000 |

| >80~120 | ≤4000 |

|

|

|

|

1,Power to weigh and drop anchor

(1) Start the electric oil pump group

(2) Close the clutch of anchor drum

(3) Loosen the brake(Automatically open when hydraulic control)

(4) Operate manual / solenoid directional control valve to the weigh and drop anchor position.

2,Power to mooring

(1) Start the electric oil pump group

(2) Close the clutch of mooring drum

(3) Loosen the brake(Automatically open when hydraulic control)

(4) Operate manual / solenoid directional control valve to do mooring work.

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate

Contact us

Add:No. 250 Songxing West Road Shanghai China, Post Code 200940

Inquiry Email: [email protected]

Whatsapp:0086-13564780885

Tel:0086-21-36120339, 0086-13564780885

Skype:yanfortune

Web: www.sinooutput.com

For other requirements please send this email

[email protected]